Warehouse Automation & Robotics

Warehouse Consultancy » Warehouse Automation and Robotics

Automation is transforming the warehouse and logistics industry as businesses increasingly deploy technology to replace the tasks previously undertaken by people. This reduces distribution costs, boosts operational resilience, increases accuracy, and improves the efficiency of a distribution centre. BoxLogic have three core objectives to our warehouse automation projects; to evaluate a range of solutions to determine if there is a financial return on investment; to identify the most appropriate technology; and to design an end-to-end solution concept.

What is Warehouse Automation

Automation in the warehouse can be defined as using technology to replace manual processes within a warehouse. Automation can reduce labour resources, both physically and digitally with different levels of deployment; from basic mechanisation (utilising discrete items of MHE such as conveyor), to system automation (implementation of a Warehouse Management System) through to integrated automated solutions (deployment of a goods-to-person picking system).

Benefits of Warehouse Automation

Businesses invest in automation in warehousing to, primarily, reduce operational costs. But wider benefits are available with the main reasons being:

Benefit | Description |

|---|---|

High labour costs | Typically, the single biggest factor as areas with higher labour costs generate larger savings from replacing labour with MHE |

High footprint costs | High footprint costs generate larger savings from the reduced operating space, especially in buildings with higher clear heights |

High throughputs | Larger throughputs allow the investment costs to be spread over a greater number of tasks |

Steady demand profile | Any investment needs to be sized appropriately and larger peak-to-average throughput ratios require greater automation capacity, and therefore cost, that might only be used during one or two weeks of the year |

Online order fulfilment | Online orders take more resource to fulfil than wholesale orders or store replenishment, therefore automation can save more labour due to the lower productivities of a manual operation |

The Role of Robotics in Warehouse Automation

Robotics is a relatively recent addition to the automation of warehouses, but they have had a significant impact in the form of Autonomous Mobile Robots (AMR) offering various goods-to-person picking and sortation solutions in addition to robotic arms that can be used for a range sorting, stacking, and even picking.

Although well suited to manufacturing environments, warehouse robotics can be used across any industry or sector but typically require higher throughputs and consistent demand profiles.

How BoxLogic Can Help

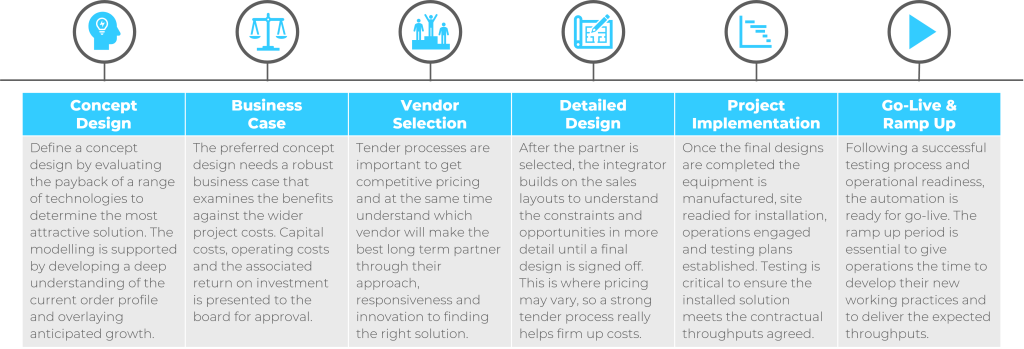

There are several stages to delivering a warehouse automation project and BoxLogic can support your operation throughout the entire process, although we particularly specialise in the early stages from concept design through to vendor selection.

Project Stage | How Can BoxLogic Help |

|---|---|

Concept Design | Evaluate a range of feasible technology options to determine the solution(s) that offer the best return on investment. The preferred technology is worked into an end-to-end concept design supported by CAD drawings, 3D renders, implementation timeline and equipment schedule. |

Business Case | Support in the creation of a robust business case of the preferred concept. We use our vast experience to incorporate the wider benefits and costs of warehouse automation to give confidence in what is being presented to the board for approval. |

Vendor Selection | Leading or supporting the process of selecting a vendor through a tender to achieve a range of fully informed and competitively priced proposals. We use our extensive knowledge of the industry and proven process to inform and support you to make the best long-term partner for your business. |

Detailed Design | Work with the preferred vendor to take the sales concepts and build them into a final design for manufacture. Our valuable experience challenges the integrators designs, value engineering where possible and ensuring that the agreed meets the objectives of the original business case. |

Project Implementation | Define, oversee, and review the testing processes to ensure that the physical and software elements of the installation are hitting the contractual agreements agreed in the sales process. We can also provide experience resource to project manage or support the steering committee to make the right decisions to be made at the right times throughout the project. |

Go-Live & Ramp Up | Work closely with the operation to plan and execute a realistic ramp up of volumes as the operations teams adapt to the new ways of working in an automated warehouse system. |

Our Process

BoxLogic specialise in the early stages of your warehouse automation journey. Our independence and ability to compare a wide range of technologies on a like-for-like basis mean that we can identify the solutions that are most appropriate for you. No two projects are the same, but a typical project approach is outlined below.

We develop a strong working understanding of your warehouse and operating model by facilitating a kick-off workshop and interviewing key stakeholders to enhance our understanding and build a picture of the project requirements.

We analyse representative data sets to understand current operational flows. These are overlaid with growth projections to create a ‘planning base’. This is used as a key input to the option modelling phase.

Our consultants agree a shortlist of feasible options with the client project team. We then create bespoke models to evaluate the capital cost, operating cost, footprint, and service levels of each option. A preferred solution is then agreed for further development based on the return on investment and appetite for capital investment.

We work with you to further develop the preferred technology into an end-to-end solution and produce a concept layout in CAD. We can even produce 3D renders or a virtual reality flythrough of the proposed concept. Our team collaborate with your finance team to build a robust business case for board approval and to define a transition plan to the future state solution.

We develop a comprehensive tender pack detailing the solution requirements to issue to the shortlist of agreed vendors. Our team coordinate the Q&A process while vendors create their sales proposals. After reviewing proposals, refining solution designs and costs, visiting reference sites a contract award is made.

Our consultants work with your team to review the contract in the agreed form, making recommendations where necessary. We can also provide expert guidance through the detailed design, implementation, and go-live stages to ensure that the built solution meets the requirements set out at the start of the process, mitigating risks along the way.

Case Study

Learn about how we delivered value for our client on a warehouse automation evaluation and end-to-end concept design project.

Challenge

An industry leading publishing house distributing 75m units per annum from its UK DC. The warehouse had exceeded capacity, requiring costly off-site storage. The client wanted to evaluate automation options of the bulk store and forward pick face without initiating a lengthy tender process.

Project Approach

- Baseline the current volumes by undertaking rigorous analysis of the throughput, storage, and operational cost data. Overlay growth scenarios and build material flows.

- Agree and model a range of manual, mechanised and automated options for both the bulk store and forward pickface, calculating the capital costs, operating costs and return on investments.

- Develop the design of the preferred concept incorporating the end-to-end processes of inbound, automated packing and despatch.

- Support the creation of a business case by refining resource assumptions and providing inputs into the project lead of the finance workstream.

Results

BoxLogic provided the client with an end-to-end concept design incorporating a manual bulk store and automated forward picking solution. Modelled capital and operation budget costs over the design horizon informed a thorough business case that was submitted for board approval. Comprehensive CAD layouts, 3D renders and a virtual reality model illustrated the future concept in detail allowing the concept to be socialised across internal stakeholders.

Why Work With BoxLogic

Warehouse automation has can completely transform the shape and cost profile of your operation but as with any investment, there is risk and the potential to not achieve the desired return on investment. It is important to have the right level of expertise to support you through your automation journey.

- Deep expertise in warehouse automation technologies and designing concepts

- Independent advice to look across the market and identify the right solution for your operation; be it automated or manual

- Ability to compare different technologies in a complex on a like-for-like basis and evaluate a payback before going to tender

- Capability to support the end-to-end project from concept design to implementation and go-live

- Robust tender methodology to compare different vendors solutions on a like-for-like basis

GET IN TOUCH TODAY

Complete the form and one of our skilled consulting team will be in touch to discuss your warehouse and logistics project today.

Alternatively, give us a call or send an email.

- +44 (0) 118 309 4030

- enquiries@box-logic.co.uk

Frequently Asked Questions

The use of automation in warehouses is to replace or complement the activity that would ordinarily be carried out by people. There are technologies that can be used in almost all processes from inbound to picking to packing and despatch. Most warehouses use automation to replace the labour-intensive tasks, the slowest for people to perform.

Generally, these provide the best investment returns and are found in the picking, packing, and sorting processes, although other areas are possible too. Goods-to-person picking replaces much of the walking activity an operative would do in a manual environment for putaway and picking. Automated packing machines reduce the number of packing operatives required. Automated conveyor or AMR sorters speed up and reduce the labour requirement in sorting parcels into different carriers.

Warehouse automation has its limitations, and it is extremely rare to find a warehouse without some form of human processing. While it is technically possible to automate almost every standard warehouse process, it can be prohibitively expensive to do so. This might be because of low throughputs, low labour or space costs, frequently changing handling requirements or otherwise.

Using an ASRS (Automated Storage and Retrieval System) with G2P (Goods to Person) picking is one of the most common and best investments an operation can make, but it still requires people. G2R (Goods to Robot) picking will be the next frontier of warehouse development and there are many examples of this solution using robotic arms. However, they are a significant investment, relatively slow in speed despite the use of AI, and still be unable to respond to the variety of challenges a human can.

Most warehouses have no automated equipment fitted. The term warehouse, however, includes a lot of small businesses with very small facilities where automation and robotics just wouldn’t be feasible. Some estimates state that 15% are mechanised whilst only 5% of warehouses have advanced automation equipment.

However, the number of warehouse operators considered installing automated equipment in their facilities is growing all the time as the types of technology grows, equipment costs rise while people and space costs rise. Warehouse property is also gearing up for the increase in automation with certain features to support this for example, larger power supplies, greater clear heights and stronger floors creeping into the speculative build specifications.

The cost to automate a warehouse depends on a wide variety of factors, meaning it will be different for every operation. These factors include the type of technology solution, the breadth of the solution (i.e., how many of the processes are covered by automation), the peak throughput requirements and many more.

A relatively small G2P solution might cost between £1-3m whilst larger end-to-end solutions for the grocery sector can cost upwards of £100m for the equipment and installation. The costs of internal project management can also be significant as automation requires a change of operating, people, and culture to make it a success.