Warehouse Management Systems

Warehouse Consultancy » Warehouse Management Systems

What is a Warehouse Management System

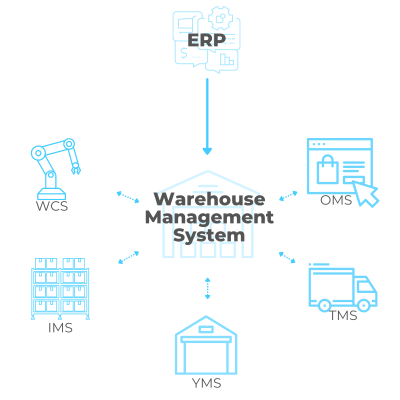

A Warehouse Management System (WMS) is a type of software that controls the warehouse processes, enabling and tracking the movement of goods into, within and out of a distribution centre. They are used to drive efficiencies in an operation, plan and prioritise workloads and maintain an accurate stockholding.

WMS software is combined with other software and hardware to capture each ‘transaction’ or change in the state of an inventory unit. It is integrated with Enterprise Requirement Planning (ERP) or Order Management System (OMS), amongst others, to communicate when certain tasks have been completed, for example; when a purchase order has been received, a customer order has been despatched or the quantity of an inventory item adjusted.

A WMS will process all the main tasks that take place in a warehouse including the receipt of goods, putaway of goods to a storage location, replenishment of goods to a pickface, picking of goods on an order, packing and shipping using a range of hardware and barcodes.

Types of Warehouse Management Systems

Warehousing Management Systems can be categorised in a few ways:

Integrated vs Standalone

An Integrated WMS is included within a businesses existing ERP or back-office software either as standard or as an additional module. A Standalone WMS is a specific piece of software focused only on providing warehouse management functionality. It needs to be able to speak to other systems to provide information, typically via EDI or API interfacing. The key trade-off is ease of integration versus warehouse functionality. Standalone systems usually offer more advanced functionality, but it requires more systems to talk to each other.

On-premise vs Cloud

On-premise software is installed locally on in-house servers. Cloud software is hosted on the software provider’s or a third party’s server. A businesses decision will depend on its wider IT policy and whether it is looking for greater flexibility, reliability and security or it doesn’t want the headache of maintaining and updating its own servers and systems.

Standard vs Customised

All WMS come with a standard package that customers can install with ‘out of the box’ functionality. Some operators require a degree of customisation to their processes and therefore need resource code and create bespoke functionality or algorithms. Customising a WMS is an expensive process with added complexity when the system needs to be upgraded but can be more aligned to a user’s needs. Typically, customisation should only happen if there is significant cost savings by operating a process differently.

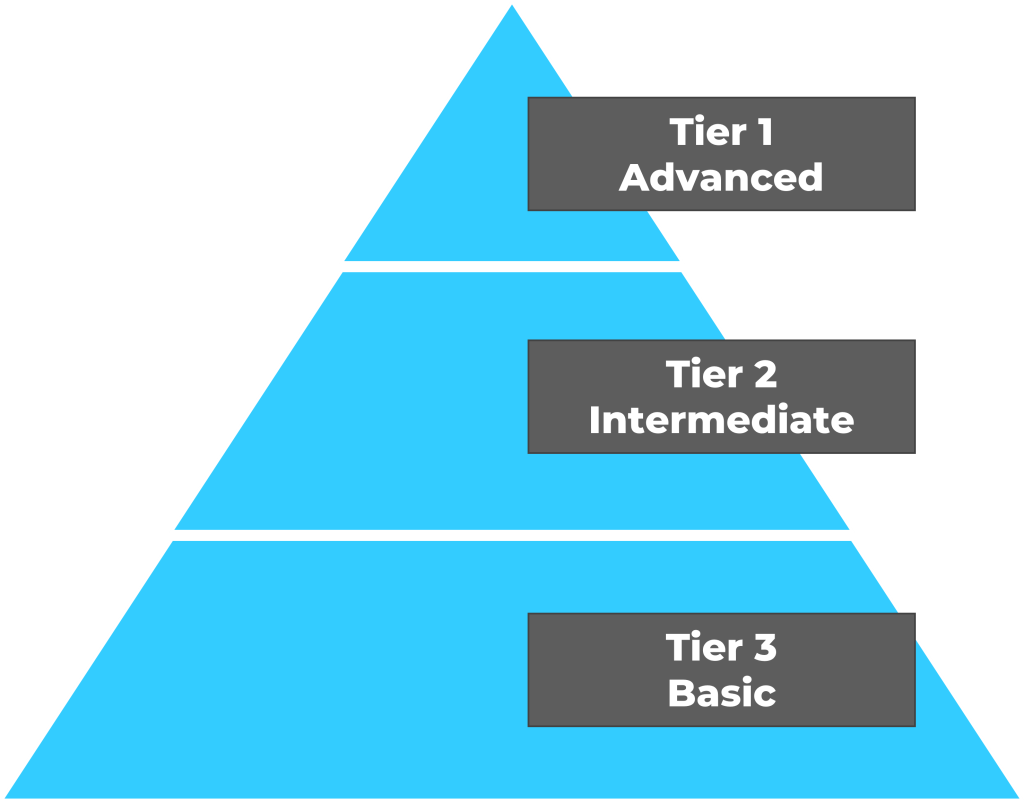

Tier 1 vs Tier 2 vs Tier 3

Each tier categorises the level of functionality a WMS offers. A Tier 3 WMS offer basic functionality to manage material flows in typically manual warehouses. Tier 2 systems also provide more advanced functionality including voice picking, RF integration and even low-level automation. A Tier 1 delivers advanced functionality that can be full integrated with a range of other software.

Benefits of Warehouse Management Systems

The benefits of businesses using Warehouse Management Systems are:

Benefit | Description |

|---|---|

Lower Operating Costs | Implementing a WMS offers significant cost savings. Using standardised WMS processes allow for a greater rate of warehouse activities whilst reducing administration costs. |

Greater Inventory Integrity | A WMS helps to control stock accuracy by tracking where stock is and enabling frequent counting of storage locations as part of a Perpetual Inventory (PI) process. Maintaining high levels of accuracy ensures product availability, reduces stock loss and damages. |

Improved Shipping Accuracy | Scanning confirmations reduce the likelihood of human error, resulting in increased picking and shipping accuracy, which leads to more satisfied customers and a higher quality of output. |

Product Traceability | A WMS provides full traceability of a products movements through the warehouse, as well as collecting which operator completed each move. This is vital in the pharma and food sectors where production issues sometimes require product recalls. The WMS can inform where each item was sent. |

Greater Storage Efficiency | Storage rules enable a WMS to group products into warehouse zones. Products could be grouped by demand, picking strategy or product type. These types of rules can increase picking efficiency and racking utilisation. |

What Other Systems are Used in the Warehouse

WMS is just one of several systems that might be used within a distribution centre. Each system fulfils a specific role but work together to manage the inputs, outputs and flows through the warehouse.

BoxLogic can also support you in the review, specification, selection, and implementation of other systems.

Yard Management Systems (YMS)

YMS is a software that monitors and manages the flow of trailers in the yard and on the docks of a distribution facility. It drives efficiencies by improving process conformance, automating gatehouse activities, and making the reducing wasted activity of yard workers. A YMS also increases site security by restricting unexpected vehicles access whilst also capturing key data including vehicle, trailer, and driver ID. It can also provide informative data by tracking on-time performance of suppliers.

Warehouse Control Systems (WCS)

WCS is a software that controls and directs the flow of goods across various material handling equipment systems. It is typically used in warehouses where automated equipment, like conveyors, lifts, and ASRS systems, is deployed. The functions of a WMS and WCS overlap and therefore a crucial question is where to draw the dividing line between the roles and responsibilities of each system.

Labour Management Systems (LMS)

LMS provides visibility of resource utilisation. It allows for resource planning as well productivity reporting and future forecasting. Whilst an LMS can be standalone system, some WMS offer this is as add-on functionality which can be used for task allocation, ensuring workload is shared efficiently amongst available resource.

Inventory Management Systems (LMS)

IMS helps to track and manage inventory through an organisation. Whilst a WMS focuses on inventory within the warehouse, an IMS takes a more holistic view and controls inventory through every area of a business including procurement, manufacturing and finished goods.

How BoxLogic Can Help

BoxLogic supports our clients throughout their warehouse management system journeys from a review of existing systems all the way to the selection and implementation of a new WMS solution.

Project Stage | How Can BoxLogic Help |

|---|---|

Review Current Systems | The current system configuration and functionality is reviewed against the requirements of the user, operation, and wider business. An assessment is made as to whether the system is fit-for-purpose and future-proofed. Improvements are also identified within the current system, if possible. |

Gap Analysis | Identification and documentation of the gaps between the current WMS against the business requirements or against the standard practice of modern systems. An assessment can then be made as to whether these gaps can be fulfilled within the current system or if a new system is required. |

Requirements Gathering | Gathering of user, operation, and business requirements across all warehouse processes. These requirements are then categorised based on whether each is a priority, standard functionality or non-standard functionality. |

Process Mapping | Capturing and mapping of the ‘as-is’ and ‘to-be’ processes against a specific, or the typical functionalities offered by the tier of warehouse management system packages that are likely to be targeted based the output of the requirements gathering process. |

Functional Design Specification | Documentation of the requirements and process maps in a comprehensive FDS which can be issued to a WMS developer or consultant for development and configuration purposes. It can also be used as part of the WMS selection tender process. |

Business Case | Support in the creation of a robust business case a new or upgraded WMS, or additional functionality. We use our extensive experience to build a business case that takes in a broad range of benefits and costs to give confidence in any submission for board approval. |

Vendor Selection | Leading or supporting the process of selecting a vendor through a tender to achieve a range of informed and competitively priced proposals. We use our extensive knowledge of the industry and proven methodology to support you to make the best solution and long-term partner for your business. |

Systems Testing | Challenging, where required, to ensure that the testing programme is fit-for-purpose and able to capture defects before a go-live. This includes load testing, integration testing, smoke testing, user acceptance testing and business readiness testing. |

Training & Go-Live Support | Providing experienced resource to work closely with the operation to plan and execute a realistic ramp up of volumes while the operation adapts to the new ways of working within the new warehouse system. This can extend to end-user training and the creation of new Standard Operating Procedures (SOP) to give the warehouse team the skills to thrive with the new system. |

Our Process

BoxLogic can deliver the end-to-end deployment of a WMS and other logistics systems. We are flexible in our approach and can contribute throughout or only in specific parts of the project, where external expertise is needed. No two projects are the same but the below outlines a typical end-to-end project approach.

We develop a strong working understanding of your warehouse operations with a site visit. A kick-off workshop and interviews with key stakeholders, including IT, help to further our knowledge of the project requirements, WMS landscape and IT infrastructure. A high-level process review with a WMS super-user completes our familiarisation.

We conduct a detailed walk through of the end-to-end warehouse processes with super users and members of the warehouse team to understand of the ‘as-is’ flows. At this stage, we take the opportunity to also document the requirements as we go through this process along with all the interfaces with other systems. This also includes understanding the flow of information through the broader IT architecture.

The current processes and operational requirements are compared to the functionality available across the Warehouse Management System marketplace to understand where the existing process and system functionality does not meet the operational requirements. We then document the gaps or non-standard processes and requirements, which inform the ‘to-be’ flows.

Current processes are updated to include the new steps to meet the operational requirements. We start with standardised processes as far as possible while considering requirements and trying to bridge the identified gaps to optimise flows. The agreed ‘to-be’ processes might be able to be deployed within the current system, and if not, they form the basis of a selection process for new WMS software.

A tender process is initiated for a new or upgraded WMS software. The agreed requirements and process flows can be documented in the form of a Functional Design Specification as part of a tender process. A shortlist of appropriate solution providers is provided with a comprehensive RFQ pack. Vendor solution proposals are submitted and reviewed to select a preferred vendor based on a blend of financial and non-financial criteria.

Delivering a successful project with experienced support in the project management, testing, training and go-live processes. We offer a flexible approach; either leading the project delivery or playing a more supporting steering role. A more active role is usually advised during the design, testing, training and go-live process with much less activity during the ‘Build’ process, which is executed by the WMS provider.

The testing process captures defects for resolution before go-live and is used structured to support the overall change management process, particularly with User Acceptance Testing and Training. Our extensive data validation and cleansing skills are utilised during the Data Upload process pre-go-live. Post go-live support can also be provided but is usually led by the WMS provider.

Case Study

Find out how BoxLogic supported Virgin Wines to deploy a new warehouse management system.

Challenge

Virgin Wines is one of the UK’s leading online wine retailers operating from two warehouses in the North West. The incumbent warehouse management system was more than 15-years old and no longer supported the businesses operational requirements and growth ambitions. Virgin Wines needed expertise to review its requirements, select a new WMS solution and implement support.

Project Approach

- Gather operational requirements and map processes to form the basis of a tender document to be issued to the market

- A detailed Request for Pricing (RFP) document was compiled to a shortlist of vendors to produce detailed and fully costed proposals while BoxLogic provided input to resolve technical questions between both parties

- Vendor proposals were evaluated and accompanied by reference site visits and interviews. Multiple presentations between the vendors and Virgin Wines helped Virgin Wines to shortlist two solution providers to progress discussions

- BoxLogic provided specialist input through the evaluation and negotiations process to support Virgin Wines to make an award to the preferred partner

- Support throughout the testing process to capture defects and prioritise their resolution

- Creation of Standard Operating Procedures (SOP) to document the new ways of working and roll out training to the operational team

- Leading the cut over process on the go-live weekend with a validated and cleansed Data Upload and resolving initial teething problems

Results

BoxLogic provided Virgin Wines with the tools and expertise to select a new Warehouse Management System, configured with up to date processes to help meet their operational requirements and growth ambitions. Our support covered the end-to-end process including project management and delivery of a successful go-live across a weekend as part of a phased rollout.

You can read more about our case study, including the testimonial of our client at Virgin Wines.

Other BoxLogic Case Studies

Why Work With BoxLogic

Warehouse Management System projects can be high risk and complex. It is important to have the right level of expertise to support you through your systems journey, whether you are looking to upgrade within your current system or deploy a completely new solution.

- Deep expertise in the warehouse and logistics systems including WMS, ERP, YMS, WCS and more

- Independent advice to look across the complex market and identify the right solution for your operation

- Capability to support the end-to-end process and deliver a consistent focus throughout

- Robust tender methodology to compare different vendors solutions on a like-for-like basis

- The ability to communicate effectively across levels of the business and knowledge of systems

GET IN TOUCH TODAY

Complete the form and one of our skilled consulting team will be in touch to discuss your warehouse and logistics project today.

Alternatively, give us a call or send an email.

- +44 (0) 118 309 4030

- enquiries@box-logic.co.uk

Frequently Asked Questions

There are three main benefits of a WMS; Inventory Integrity, Operational Efficiency and Traceability.

Inventory Integrity – a WMS helps to control stock accuracy. Maintaining high levels of accuracy ensures product availability.

Operational Efficiency – using a WMS can be much more efficient than traditional manual processes. Standardised processes allow for a greater rate of pick and despatch activities which often translates into a reduction of operating costs.

Traceability – a WMS tracks product movements through warehouse processes. Typically, each process step is recorded in the WMS, providing traceability of where the products are, have been to, as well as which operators have interacted with them.

A WMS can be configured and customised to manage all flows within a warehouse. The most common processes, however, are:

Goods Receipt – check in and input of products into the WMS.

Putaway – transfer of products from the receiving dock to a storage location.

Storage – the safe and logical storage of products to enable fast and accurate picking.

Picking – the process of identifying the required items on an order and moving them to the packing or marshalling areas. A WMS often contains several picking methods (e.g. box pick, sequence pick, decrement pick etc.)

Packing – moving picked products into shippable storage media. Transferring products from totes or trollies to shippable cardboard boxes, or stacking products onto pallets ready for despatch.

Shipping – loading pallets or parcels to vehicles and despatching from the warehouse. From this point products are shown as leaving the warehouse and no longer appear in the inventory. Also known as ‘dispatching’

Stock – the processes required to maintain inventory accuracy. For example, perpetual Inventory (P.I) counts, stock checks and stock movement. Some operations may also require wall-to-wall counts annually.

The WMS software market has many different providers offering a wide variety of solutions to meet the needs of different sized operations. A leading authority on the topic is Gartner, which divides the market into Leaders, Challengers, Visionaries and Niche Players. The leading providers tend to be Manhattan, Blue Yonder and SAP but there are a whole host of other providers on the market that might be better suited to many businesses.

Other software used within a warehouse can include Yard Management Systems (control of yard activities), Warehouse Control Systems (control of MHE), Labour Management Systems (forecast, plan labour and performance visibility) and Inventory Management Systems (trace stock across multiple warehouses).

SAP is an Enterprise Resource Planning Software (ERP). This means SAP has many modules available within the system, one of which is a warehouse management system, called EWM. They offer different levels of WMS dependant on a business’ required functionality.