Harry Stafford, Consultant at BoxLogic tackles the subject of manual storage options for smaller items, following up on his previous post about manual bulk storage options.

In this, Harry looks at the warehouse design options where items are not stored as pallets, most commonly used in ecommerce environments.

Introduction to Manual Small Pick Storage

This post is included as part of our automation technology series as it is important to cover manual solutions as part of any discussion about automation. Every investment in warehouse automation needs to be justified against a manual, base option. The operational cost savings of automation must exceed the additional investment of automation over a manual investment within a reasonable time period.

Small pick storage is a method of storing product where it is held in relatively small quantities, from a cube perspective and picked as units, rather than cases. It is most commonly found in ecommerce operations or those with a relatively high SKU count, where the pickface is made as small as is feasible to maximise the productivity of the picking and putaway process. Several examples of small pick storage are outlined within this article.

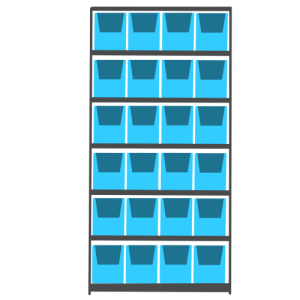

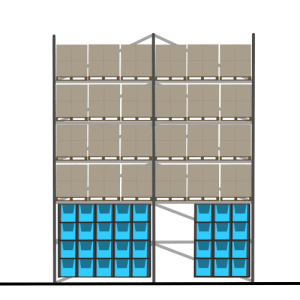

Industrial and Long-Span Shelving

Shelving is comprised of single deep locations, side-by-side in opened faced bins. Bins can come in a variety of sizes to accommodate the differing SKU dimensions and typically are erected up to 2 meters high to maintain easy human operative access. Given the low height of shelving, it is often found as part of a multi storey ‘pick tower’ or mezzanine. Pick shelving is suitable for small SKU’s that require single item picks making it very suitable for ecommerce.

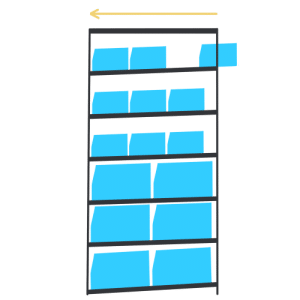

Carton Live Shelving

Like pick shelving, carton live racking also operates with a pick face of bins of various sizes. The difference being carton live is a muti-deep solution that is often used in conjunction with roller conveyor to replenish cartons or totes from the back of the racking. This allows for a FIFO operation that is denser and more efficient. Carton live storage can be fitted on the bottom level of pallet racking or as individual shelving units. It is most appropriate for high-throughput operations where replenishment is conducted in larger quantities and therefore pickface stock depths are greater.

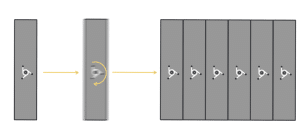

Mobile Shelving

Mobile shelving is a smaller version of the mobile pallet racking, described in the previous article. Shelves are mounted to mobile bases that are rail assisted. The units are moved manually via a hand crank to create an aisle for operative access. The compact nature of the units saves on footprint and offers security. This type of storage is only suitable for items with low or no throughput and is typically used to archive books, files and fashion.

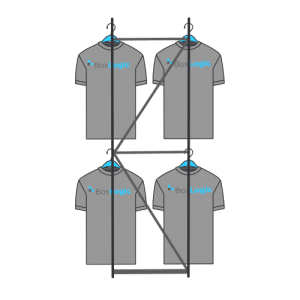

Hanging Racking

Hanging garment solutions are typically composed of a monorail on which to store garments on a hanger. While not as dense as carton storage, hanging racking does have ease of access and may be employed when the boxing of apparel is not suitable for the garment. A Goods on Hanger (GOH) bay is flexibly designed and usually has either one rail, for long garments (e.g. dresses) or two rails in the height for storing standard length items (e.g. tops). SKU locations are separated by tags that sit along the rail, rather than completely distinct locations.

Speed Cell / Storeganizer

Speed cell and Storeganizer are branded products that use high-strength textile hanging locations suspended on monorails. The presented pick locations are similar to pick shelving but are lightweight enough to be moved side-to-side manually to allow access to pick locations behind it. Speed cell can be configured up to 3 levels deep and is designed to fit within a standard pallet racking location. This storage is a very compact solution suitable for single item picks with small, low weight items making it ideal for apparel and e-commerce. This is especially the case for operations with high SKU counts, a standard or concentrated SKU Pareto and where existing pallet racking infrastructure is in place.

Mezzanines

Mezzanines are a way to make use of any additional vertical space, or clear height, to increase the cubic density of a warehouse. Depending on the height of the building, mezzanines usually go up to 3 levels high above the ground level and can be utilised for storage, picking, packing or office space. There are different types of mezzanines.

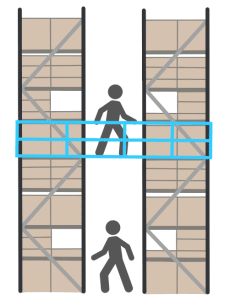

Rack Supported Mezzanine

Rack supported mezzanines are built within a racking structure, where an aisle is created at within the racking structure. This space is typically used for human picking only as rack support has a relatively weak load bearing. Another key benefit is the ability to deploy mezzanine floors above a lower pallet storage environment. It is a lower cost form of mezzanine; however, it can be inflexible as key elements cannot be adjusted once built. It is therefore important to carefully consider the rack depths and aisle widths before committing to a design.

Free Standing Mezzanine

Free standing mezzanines sit separately from any other structures in the building and are supported by their own steel columns, they will also support utilities such as sprinklers and lighting. Unlike rack supported solutions, they allow for an open area below the mezzanine for picking and packing and can be reconfigured far easier than structured mezzanines. Free standing mezzanines, unlike structured mezzanines, can be installed after the building has been built.

Structural Mezzanine

Structural mezzanines are made from concrete and steel and therefore are the highest load bearing solution. They are however the most expensive and time consuming to install as they are erected during the construction of the building. Structured mezzanines do, however, have the highest load bearing of all mezzanines and can therefore support warehouse operations that require forklift trucks (FLT) or order picking MHE.

Summary

There are several manual storage options to choose from and the right solution for each operation will depend on its and the warehouse facilities unique characteristics. Mezzanines, or pick towers, are a common way to maximise the storage density of a building and can be combined with any of the manual storage options outlined within this post. Mezzanines can also be combined with some automated options with extra design features, and these will be outlined in some future articles.

If you need advice on the right storage type or combination of storage types, then get in touch with our warehouse consultants to find out how we can help you design a dense and efficient operation in your distribution facility.