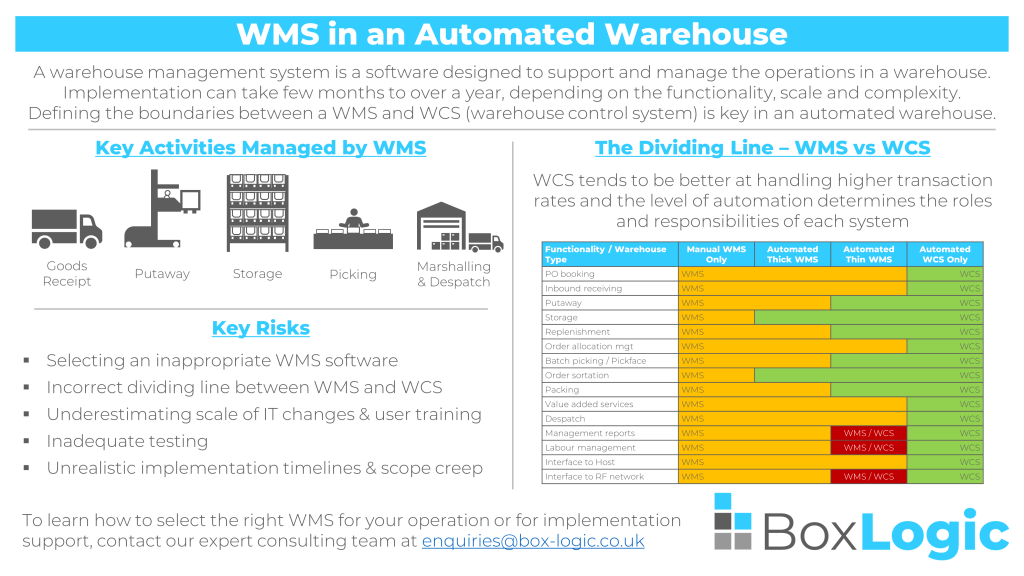

A warehouse management system is a software designed to support and manage the operations in a warehouse. Implementation can take few months to over a year, depending on the functionality, scale and complexity.

Defining the boundaries between a WMS and WCS (warehouse control system) is key in an automated warehouse.

Key Activities Managed by a WMS

A WMS is responsible for the management of the processes in the warehouse and is integral to the following prime activities, in addition to many others.

Goods

Receipt

Putaway

Storage

Picking

Marshalling

& Despatch

Key risks of WMS implementations?

- Selecting an inappropriate WMS software

- Incorrect dividing line between WMS and WCS

- Underestimating scale of IT changes & user training

- Inadequate testing

- Unrealistic implementation timelines & scope creep

The dividing line - WMS vs WCS?

WCS tends to be better at handling higher transaction rates and the level of automation determines the roles and responsibilities of each system.

The table shows a guide of where this dividing line should be for each function:

Functionality | Manual WMS Only | Automated ‘Thick’ WMS | Automated ‘Thin’ WMS | Automated WCS Only |

|---|---|---|---|---|

PO Booking | WMS | WMS | WMS | WCS |

Inbound Receiving | WMS | WMS | WMS | WCS |

Putaway | WMS | WMS | WCS | WCS |

Storage | WMS | WCS | WCS | WCS |

Replenishment | WMS | WMS | WCS | WCS |

Order Allocation Mgmt | WMS | WMS | WMS | WCS |

Batch Picking/ Pickface | WMS | WMS | WCS | WCS |

Order Sortation | WMS | WCS | WCS | WCS |

Packing | WMS | WMS | WCS | WCS |

Value Added Services | WMS | WMS | WMS | WCS |

Despatch | WMS | WMS | WMS | WCS |

Management Reports | WMS | WMS | WMS / WCS | WCS |

Labour Management | WMS | WMS | WMS / WCS | WCS |

Interface to Host | WMS | WMS | WMS | WCS |

Interface to RF Network | WMS | WMS | WMS / WCS | WCS |

To learn how to select the right WMS for your operation or for implementation support, contact our expert consulting team at enquiries@box-logic.co.uk