Logistics Network Strategy

Logistics Consultancy » Logistics Network Design

What is Logistics Network Design

Logistic network design (also known as distribution network design or logistics network strategy) is a strategic design project where the objective is to define the lowest cost solution that meets the customer proposition. The logistics network is the way in which goods flow between manufacturers and customers, via the various warehouses and is a critical element of the supply chain.

The logistics network includes the size, location, and scope of the physical infrastructure (factories and warehouses); the frequency and timing of replenishment or despatch transport; the supporting logistics systems; the inventory holding across the network and the reverse logistics or returns process.

Defining the most appropriate distribution network involves understanding, among other things, how many warehouses should be operated, where each warehouse should be located and what is its role, how much inventory should be held at each stocking location and how big each warehouse needs to be based on the allocation of customers or stores it serves. Transport is also a significant factor, with key considerations including the replenishment frequency, the vehicle fleet size and mix and use of own-fleet or subcontract.

BoxLogic’s robust modelling techniques assess a variety of different network configurations and options to identify a preferred solution for your supply chain. The preferred network configuration is selected based on a variety of factors including overall cost, service lead time and resilience to change.

How BoxLogic Can Help

BoxLogic can design or optimise logistics networks in a variety of ways, depending on the actual requirements of each business. Common scenarios our team of logistics consultants deal with include:

Project Stage | How Can BoxLogic Help |

|---|---|

Logistics Network Design and Optimisation | A study to identify the most appropriate configuration for a distribution operation. Whether a business is looking to create a strategic roadmap for how to develop its logistics network over time or are coming to the end of a lease on key infrastructure, this looks holistically at a range of the relevant cost and service implications. |

Capacity Development | Determine the strategic roadmap for how a logistics network should develop over time with growth. This considers where additional sites should be added or where existing sites should be moved to as leases expire to create cost efficiency or network coverage of a country or region. |

Locational Analysis | Analysis of inbound and outbound volumes to establish the centre of gravity (or centre of gravities) of a distribution network. Centre of gravity analysis can be a useful tool in identifying the potential location(s) of warehouse facilities. This might be particularly useful where the lease of a current warehouse facility is due to expire and a study needs to be conducted to determine whether to extend or move to a new location. |

Infrastructure Review | A review of logistics infrastructure to assess its suitability for an operation in terms of its size, location and functionality. Reviews can be carried out on either existing or potential logistics facilities. |

Service Level Optimisation | Evaluation of a range of warehouse and transport options to improve the service to customers within a distribution network. This will involve identifying the changes required to achieve alternative service levels. |

Cost to Serve Modelling | Assess the costs of fulfilment of a logistics operation. One example might be to look at the fulfilment costs of different customers to inform which accounts are profitable and loss making. It can also be applied to products or product categories. This helps feedback into the pricing and account teams to help the business become more profitable. |

Outsourcing and Insourcing Evaluation | Evaluate the costs and benefits of using outsourced solutions as part of the logistics network configuration in addition to assessing the requirements of taking operations back inhouse. |

Our Process

Strategic distribution network design projects are a core capability for BoxLogic and we use our tried-and-tested approach to deliver a recommended network configuration for our clients. All projects have different requirements, but a typical project approach is outlined below:

We develop a strong working understanding of your logistics network and operating model by facilitating a kick-off workshop and interviewing key stakeholders to enhance our understanding of the project requirements.

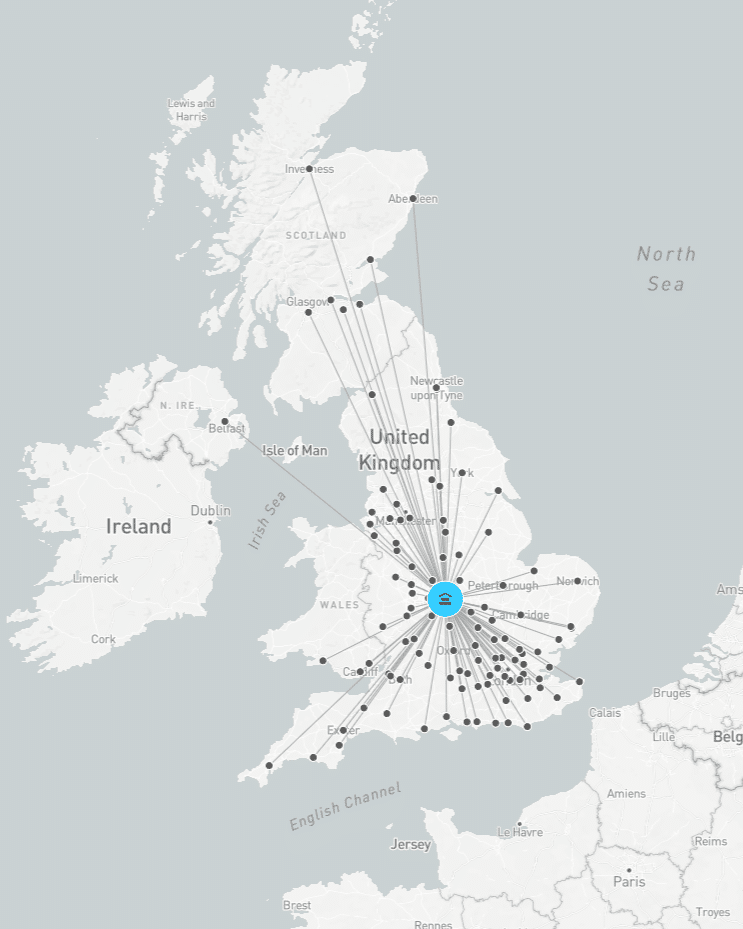

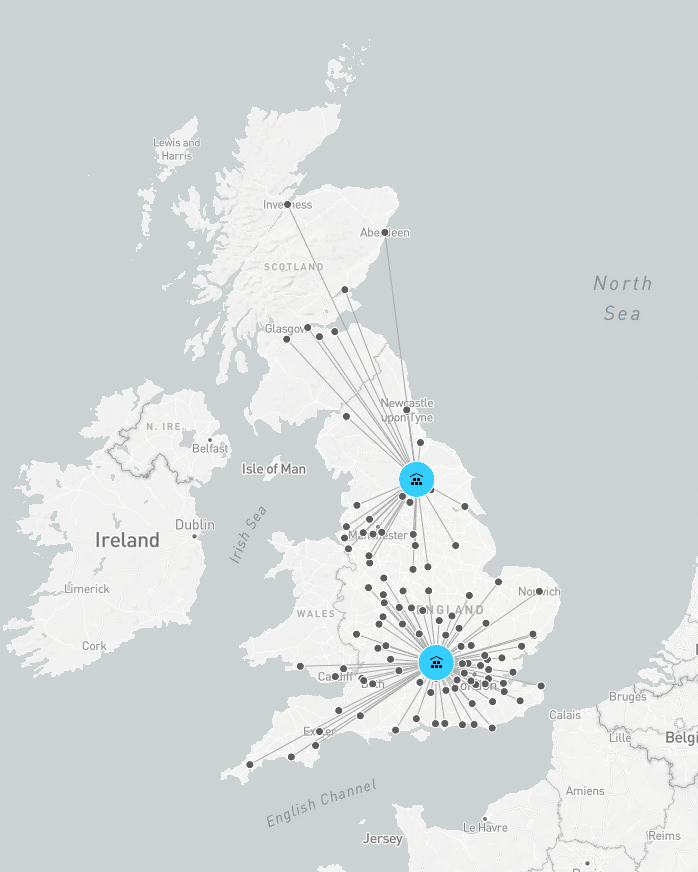

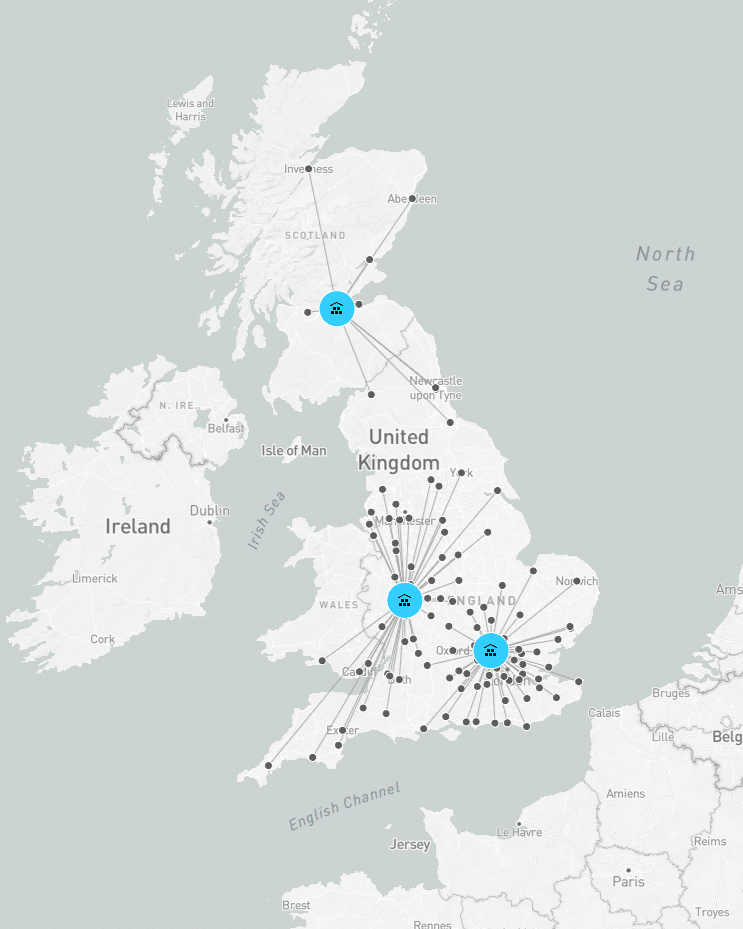

We analyse representative data sets to understand current operational flows and produce visualisations of the current network to illustrate how it works and where the opportunities lie. We perform centre of gravity analysis to identify potential warehousing locations. Operational flows are overlaid with growth projections to create a ‘planning base’. This is used as a key input to the option modelling phase.

Our consultants agree a shortlist of feasible options with the client project team. We then create bespoke models to evaluate the financial and service level implications of each scenario. Sensitivity analysis is produced to test each option under a range of scenarios to ascertain its robustness. A preferred solution is then agreed for further development.

We work with you to further develop the preferred solution into an end-to-end solution with a road map for transitioning to the future state network. We also support the building of a business case for board approval.

Case Study

Find out how we helped our client to optimise a European distribution network.

Challenge

A global FMCG business wanted to review its European logistics network to achieve lower costs, faster delivery lead times and greater synergies between its different business units, each with its own logistics unique infrastructure.

Project Approach

- Analysed the inbound and outbound logistics flows over the last 12 months, with focus paid to the cost of transport and warehousing

- Agreed a range of individual modelling scenarios across the network to evaluate based on the clients’ ideas and BoxLogic’s own deep logistics network expertise

- Defined transport, property and labour costs of operating out of 70 locations across Europe using regression analysis and demographic data to model alternative scenarios

- Modelled and evaluated each of the agreed scenarios to identify the options which provided the largest benefits within the logistics network

- Combined the preferred options into a holistic network solution, defining the benefits by market and business unit to support internal stakeholder engagement

Results

BoxLogic provided the client with two logistics network solutions, the primary recommendation of which offered savings of 10% in direct logistics costs, with further benefits in working capital, whilst reducing the average lead time by 7%. The models were handed over to the client for ongoing refinement of the logistics network strategy.

Why Work With BoxLogic

Our team of dedicated logistics professionals are well placed to help you on your next distribution project for several reasons.

- All BoxLogic recommendations are underpinned with rigorous analysis and modelling to give confidence in our work

- Expert consultant team with the right blend of strategic and operational experience so that we can be pragmatic and innovative in our recommendations

- We use bespoke modelling tools rather than ‘black box’ software so that we can fully explain and interrogate our output

- Excellent background of delivering similar projects for businesses of all sizes across a wide range of industries

- Capability to support the end-to-end project from network configuration design to implementation of the preferred solution

GET IN TOUCH TODAY

Complete the form and one of our skilled consulting team will be in touch to discuss your warehouse and logistics project today.

Alternatively, give us a call or send an email.

- +44 (0) 118 309 4030

- enquiries@box-logic.co.uk

Frequently Asked Questions

A logistics network design comes about through several steps. Firstly, a familiarisation exercise is undertaken to get to understand the operation and the service level requirements to its customers. A detailed analysis then summarises the network flows, which can then be used to perform Centre of Gravity analysis, which inform potential facility locations.

The modelling phase then starts with defining the list of options to be modelled, whether the variables are the facility locations, facility functionality, the number of sites, etc. These options can then be modelled to determine the costs and service implications of different configurations.

The modelling outputs can then be reviewed and compared against each other to decide a preferred network that can be taken to develop the end-to-end solution further. This includes building the business case and establishing the transition plan.

Logistics network design is important because it has the potential to reduce the operating costs of a business as well as improve the service proposition to its customers. This increases customer satisfaction, improves the profitability of a business and it can also provide a differentiator to the market to attract further business.

Most distribution network design reviews originate from the expiry of a building lease or contract with a third-party logistics provider. Commitments to extend such contracts continue for multiple years and taking the time to confirm that the right approach is being taken can prove invaluable to businesses as they take advantage of the flexibility when it is available.

There are a few common logistics network models. The appropriateness of each model to a business depends on several factors including throughput volumes, storage volumes, SKU range, spread of customers and customer order profiles.

Probably the most common model is the National Distribution Centre (NDC) model, where a single warehouse distributes volumes across the whole country. This is particularly common in the UK, and other countries, where the majority of the country can be reached within a driver’s shift. A network can also include multiple NDCs where each warehouse stores and distributes a unique SKU range.

A Regional Distribution Centre (RDC) model is where the same SKUs are replicated across one or more warehouses in the same country or continent. It is frequently used where the throughput volumes are very high or where service levels require faster delivery times.

The Port-centric model is where a warehouse or production facility is located within close proximity to a port, usually ocean. This model tends to be used for networks where a significant proportion of goods are imported and/or exported.

Each of these networks can be supplemented with x-docking facilities to optimise the transport of goods across long distances. The x-dock facility takes large vehicle loads and splits them down into smaller vehicle loads for delivering on a fleet of smaller vehicles.

A good logistics network will offer a balance of efficiency and fast replenishment to customers. The optimal network for service level will come with a high cost whilst the optimal network for efficiency might not hit the customer requirements.

A logistics network must also be resilient to changes in volumes and other potential scenarios that won’t easily leave the network’s infrastructure redundant. Therefore, any logistics network design project will understand and find the network offering the best balance of efficiency and service whilst being adaptable to change.